The clothing manufacturing industry started in 1999, starting from a 200-square-meter factory. During this period, it mainly served the domestic market. It also provided OEM services for international clothing brands such as Armani, focusing on OEM services.

MES system

- HUCAI employs a Manufacturing Execution System (MES), an advanced system capable of effectively managing and controlling production activities.

- The MES system monitors and schedules each stage of the production process in real-time, ensuring efficient and orderly production. It can collect production data in real-time, helping us respond quickly and adjust production plans, thereby minimizing waste and increasing output.

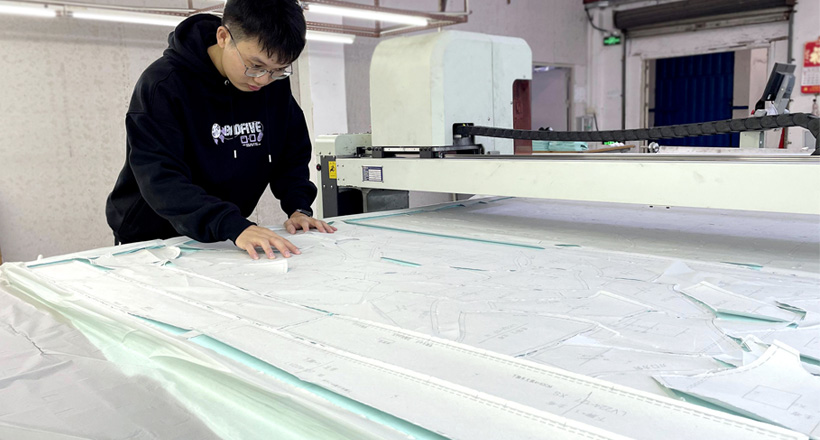

Hanging Production System

- To further boost production efficiency, we have introduced the hanging production system.

- This system uses automated conveyor belts to efficiently and accurately transfer semi-finished products between different stages, significantly shortening the production cycle. The hanging production system not only improves production efficiency but also reduces human error, ensuring consistency and high quality in our products.

The value we provide to our customers

- 1. Ensuring Timeliness: Delivery within 30 Days

- 2. Full Visibility of Production Progress

- 3.Improved Quality